Intelligent Industrial Solution

Provides the one stop solutions of the artificial intelligence vision for the global customers

Introduction

Intelligent industrial solution provides the one stop solutions of the artificial intelligence vision for the global customers. At present, there are many cases that they are successfully implemented in the LCD panel, electronic products, cosmetics and automobile industries, and they are well received by customers. In the LCD panel industry, we successfully launches the first actual production line in China, and has the experience in the implementation of automatic defect classification (ADC) system for more than one year.

Intelligent industrial solution includes the industry detection algorithm package, such as complete self-developed CV defect positioning IP package, AI automatic classification system, LCD panel/3D cover plate/silicon-based/electrical equipment, and can help customers to realize the quick launch within 3-5 months, achieve the goal of improving product yield, enhancing personnel efficiency and speeding up testing speed, and help customers to realize the successful transformation from traditional manufacturing to intelligent manufacturing.

LCD Panel Industry

• Array defect detection

• OLED defect detection

• Module defect detection

• CG defect detection of incoming materials

Electronic Product

• PCBA detection

• Appearance defect detection

• Package defect detection

Cosmetics Industry

• Package defect detection

• Tank level detection

• Label damage detection

Automobile Industry

• Surface painting detection

• Body parts assembly detection

• Electronic component classification test

Customer Service

Automatic defect classification

The full name of ADC is defect automatic classification, which is mainly an intelligent vision multi-platform solution for the industrial field:

• Array defect detection

• OLED defect detection

• Module defect detection

• CG defect detection of incoming materials

The iterative cleaning platform

The iterative cleaning platform of products can work with the ADC platform or be used standalone, which can shorten the data iterative cleaning cycle for the launch of new products. It mainly includes:

• Defect definition system

• Data cleaning system

• New product analysis system

• Data annotation system

• Data recheck system

• New defect analysis

The operator certification platfrom

The operator certification platform is developed to check whether the operators have the post skills of image classification and the operators meet the post skills requirements. It mainly includes:

• Large scale defect grading question bank

• New defect/new definition assessment system

• Operator level/performance assessment system

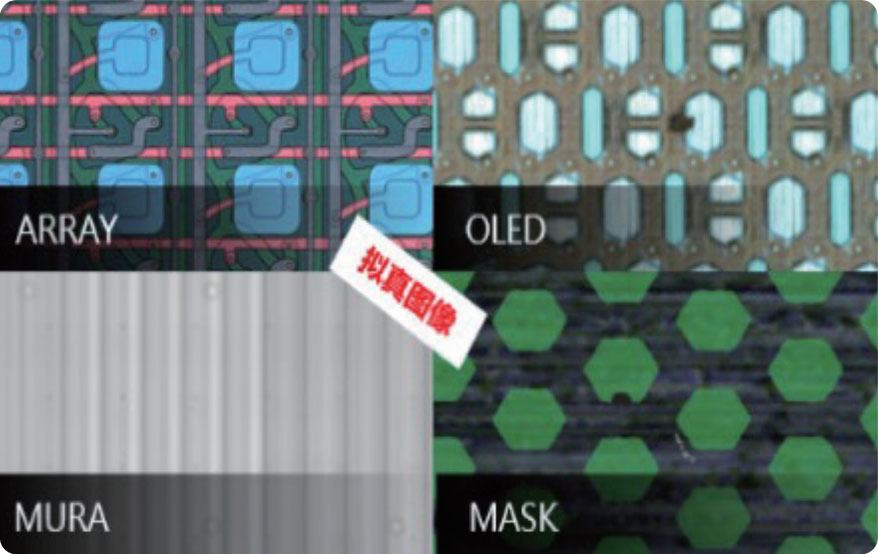

LCD Panel Industry Solutions

For the Array station, we have achieved currently:

• Full coverage of all detection sites • Wide coverage of spot check sites

For the mask process of OLED station, we have achieved currently:

• Full coverage of important coatings • Wide coverage of other coatings

For the MURA electrical testing, we have achieved currently:

• Full coverage of Killer Code • Wide coverage of normal code

Electronics Industry Solutions

The industrial vision makes it possible to realize current high-density integrated circuits and manufacture such circuits at a low cost. The suppliers of electronic materials, active components, IC package, passive components and finished electronic equipment can use the industrial vision for calibration, inspection and identification.

• PCBA inspection: Including PCB assembly verification, wafer and IC package identification, and board identification

• Appearance defect detection: Inspect the appearance of electronic products, to ensure the appearance quality of products.

• Package defect detection: Inspect the primary and secondary package, to ensure correct assembly, tamper-proof and defect free.

Cosmetics Industry Solutions

The cosmetics manufacturing features many kinds of defects, close relation to the shape and spatial state, and quick product change, which requires the algorithm to include:

• Package defect detection: Inspect the primary and secondary package, to ensure correct assembly, tamper-proof and defect free.

• Tank level detection: Mainly includes the detection of container defect, determination of package location and orientation and detection of defect or insufficient filling.

• Label damage detection: Ensure that the label is placed correctly, and there is not any wrinkle, crack, or misprint.

Automotive Industry Solutions

The industrial vision can improve the performance of most systems and compo- nents in the automotive industry. The machine vision system and image-based code readers are introduced into the production process, so that the auto parts manufacturers and auto assembly plants can achieve higher quality to meet customer needs. At present, the automotive industry solutions have covered:

• Surface coating detection: Including surface coating of automobile engines and transmissions.

• Body panel assembly detection: Including body and window assembly, final assembly verification of decorative parts, and final assembly verification of automotive.

• Electronic component classification detection: PCB detection, electrical module seal test and Electrical switch assembly inspection.

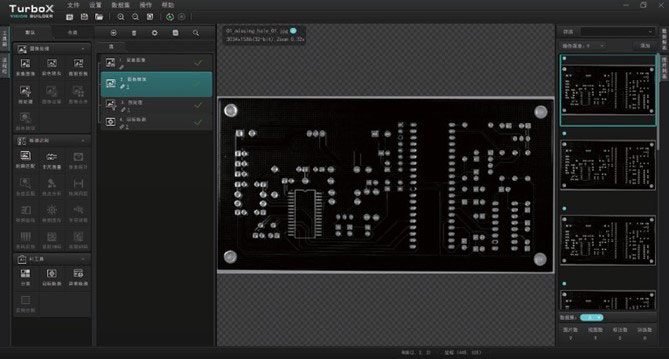

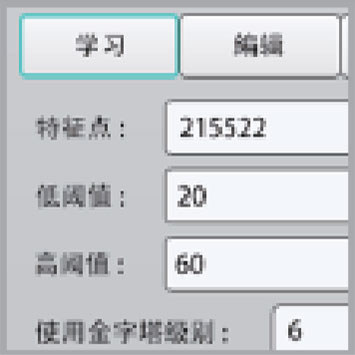

Vision Builder

TurboX Vision Builder is an intelligent industrial visual platform software based on the fusion of tradi- tional machine vision and deep learning, designed to solve complex defects problem such as location, detection, applicable to complex industrial application scenarios. It has powerful compatibility and good detection performance, as a drag-and-drop visualization algorithm development kit, it suitable for factory workers without programming background to quickly setup and use.

Features

• Short development process

• Efficient algorithm

• Comprehensive tools

• Superior performance

• Simple operation

Simple tool parameter configuration

Ric visual algorithm toolbox

CV + AI fusion algorithm workflow

Visual image processing process

Application Scenarios

It can be applied to more than 90% of industrial scenarios including new energy, semiconductor, medical treatment, 3C, automobile, food, electricity, etc

Energy

Semiconductor

Medical Treatment

3C

Automobile

Food